CASE SHARING

Integrated Energy Transformation Solution

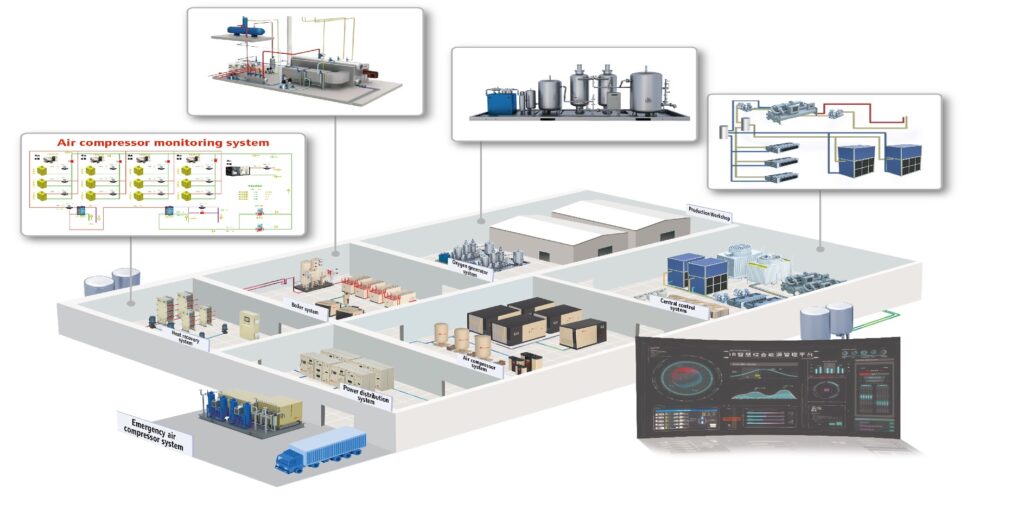

- Conducted in-depth research on user’s energy systems (refrigeration station, compressed air system, boiler, nitrogen production, cooling water system, etc.), combined with comparative analysis of energy consumption statistics, comprehensive energy-saving transformation were carried out, and established a cloud-based intelligent energy digital platform;

- The annual comprehensive electricity consumption of users was 3200 kWh. The energy-saving rate was expected to reach 20%, saving 5 million yuan annually.

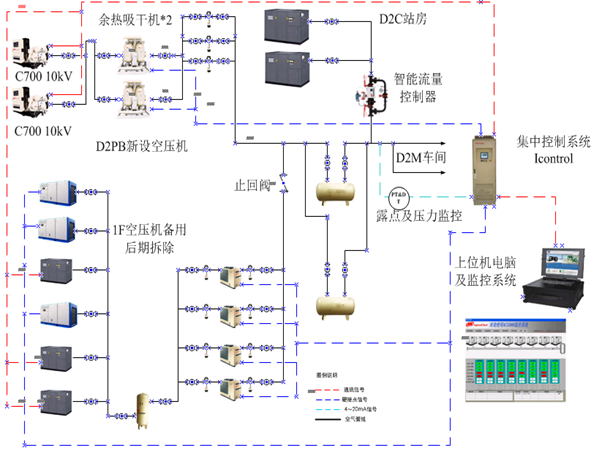

Before Transformation

- 9 air compressors(AC), GA160;

- The customer required significant amount of manpower to maintain the normal operation of the air compressor station;

- Outdated equipment with high maintenance costs, low reliability, and high energy consumption;

- Before transformation, the comprehensive gas-electricity ratio of the old station room was 0.1545 kWh/m³.

After Transformation

- Replaced all 9 AC GA160 units and the air-treatment with two C700 centrifuges and two compression heat zero gas loss suction dryers;

- Responsible for all operation and maintenance of the whole air compression station, and customers do not need to worry about it;

- After the transformation, the air compressor station can be unattended;

- Dual backup with the old system;

- Customers share not only the savings in electricity but also the savings in operation and management costs.

The theoretical energy consumption of the system is approximately 0.092 yuan/m³,

with an annual saving benefit of 74,462,000 × (0.124 – 0.092) = 2.383 million yuan.

Before Transformation

- 3 Kobelco 75kW screw air compressors + 1 ORION cold dryer + 1 Parker module desiccant dryer, large production fluctuations;

- The measured gas electricity ratio of the station was 0.18kwh/m3;

- Base gas volume was 72 million cubic meters per year, average electricity price was 0.85 yuan/kWh;

- Annual electricity consumption: 1.296 million kWh, annual electricity cost: 1.102 million yuan.

After Transformation

- Used 2 ESM75ne units, 2 ESD150 units, 1 ESD010BR-A , 10 ENLD units, 1 set of PGX4, a set of instrumentation, and 1 I control to replace the original system and built a cloud platform;

- After transformation, the station room air-electricity ratio was 0.18 kWh/m3;

- Annual electricity consumption: 0.792 million kWh, annual electricity cost: 0.673 million yuan;

- The annual saving benefit was 1.102 – 0.673 = 0.43 million yuan, with an energy-saving rate of 39%.